BibTeX | RIS | EndNote | Medlars | ProCite | Reference Manager | RefWorks

Send citation to:

URL: http://ijmt.ir/article-1-872-en.html

2- Amirkabir University of Technology

|

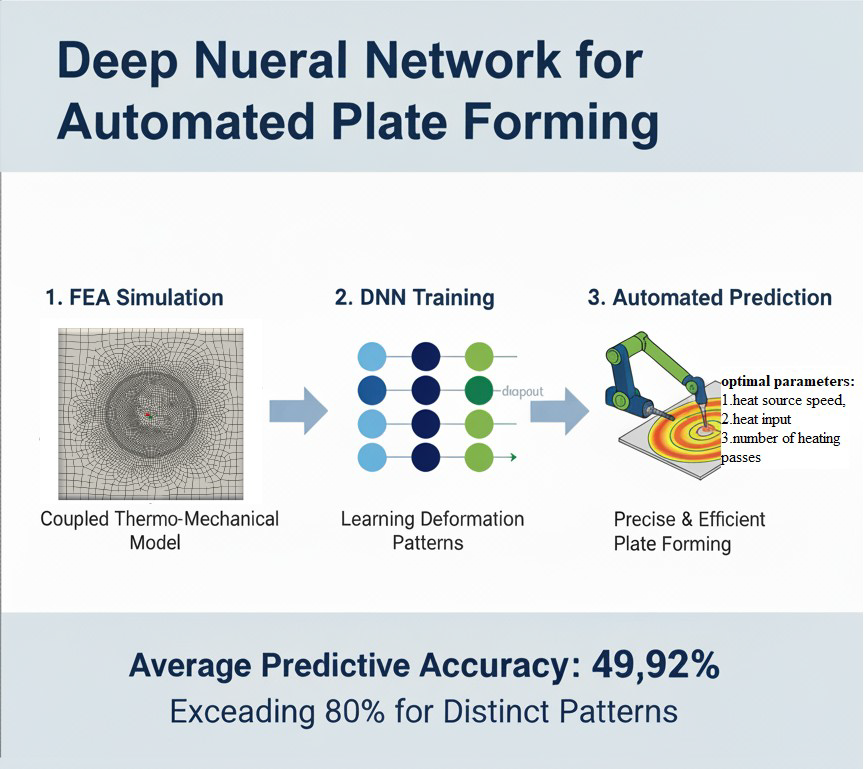

The line heating process is widely used in shipbuilding to form complex curvatures in steel plates, particularly in the bow and stern sections. However, the method’s reliance on skilled operators often leads to inconsistent results. This study presents the development of a deep neural network (DNN) model to predict optimal operational parameters for plate forming via line heating, thereby improving precision, repeatability, and automation. A coupled thermomechanical finite element model was developed using ANSYS APDL to simulate temperature distribution and deformation for various heating configurations. The simulation results were used to train the DNN, which consists of multiple hidden layers with dropout regularization to enhance generalization. The model successfully learned the nonlinear relationships between input parameters (heat source speed, heat input, and the number of heating passes) and resulting deformations. The trained DNN achieved high predictive accuracy, demonstrating its potential as a real-time decision-support tool in automated plate forming systems. This integration of FEM-based simulation and AI enables more efficient, consistent, and cost-effective manufacturing in the shipbuilding industry. The proposed DNN model achieved an average predictive accuracy of 49.92%, with performance exceeding 80% for cases with distinct deformation patterns. |

- The study focuses on developing a Deep Neural Network (DNN) to predict optimal parameters for forming steel plates using line heating in shipbuilding.

- A thermo-mechanical finite element model was created with ANSYS to simulate deformations from various heating configurations, generating the data to train the DNN.

- The trained DNN model can predict the necessary heat source speed, heat input, and the number of heating passes to achieve a desired plate shape.

- The model achieved an average predictive accuracy of 49.92%, with over 80% accuracy for cases with distinct deformation patterns.

- This integration of simulation and AI serves as a decision-support tool to enhance efficiency, consistency, and automation in shipbuilding.

| Rights and permissions | |

|

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License. |