1. Hosseinzadeh S, Gatmiri B. Bearing behavior assessment of wind turbines' s shallow foundations, comparison of gravity-based foundations and suction buckets. Ocean Syst Eng [Internet]. 2025 [cited 2025 Oct 5];15(3):241. Available from: http://techno-press.org/content/?page=article&journal=ose&volume=15&num=3&ordernum=1

2. Sampath S, Bhattacharya B, Aryan P, Sohn H. A Real-Time, Non-Contact Method for in-Line Inspection of Oil and Gas Pipelines Using Optical Sensor Array. Sensors. 2019;19(16):3615. [

DOI:10.3390/s19163615] [

PMID] [

]

3. Demoz A, Papavinasam S, Omotoso O, Michaelian K, Revie RW. Effect of Field Operational Variables on Internal Pitting Corrosion of Oil and Gas Pipelines. Corrosion. 2009;65(11):741-7. [

DOI:10.5006/1.3319100]

4. Colindres SC, Méndez GT, Velázquez JC, Cabrera-Sierra R, Angeles-Herrera D. Effects of Depth in External and Internal Corrosion Defects on Failure Pressure Predictions of Oil and Gas Pipelines Using Finite Element Models. Adv Struct Eng. 2020;

5. Rachman A, Zhang T, Chandima Ratnayake RM, Ratnayake RMC. Applications of Machine Learning in Pipeline Integrity Management: A State-of-the-Art Review. Int J Press Vessel Pip. 2021 Oct 1;193:104471. [

DOI:10.1016/j.ijpvp.2021.104471]

6. Zheng Y, Zhang Y, Lin J. System reliability analysis for independent and nonidentical components based on survival signature. Probabilistic Eng Mech. 2023 Jul 1;73:103466. [

DOI:10.1016/j.probengmech.2023.103466]

7. Wang Y, Wharton JA, Shenoi RA. Mechano-electrochemical modelling of corroded steel structures. Eng Struct. 2016 Dec 1;128:1-14. [

DOI:10.1016/j.engstruct.2016.09.015]

8. Yang Y, Wang GH, Qu Z, Zhang H, He J, Chen H. Reliability Analysis of Gas Pipeline With Corrosion Defect Based on Finite Element Method. Int J Struct Integr. 2021; [

DOI:10.1108/IJSI-11-2020-0112]

9. Cheng YF. Pipeline Corrosion. Corros Eng Sci Technol Int J Corros Process Corros Control. 2015;50(3):161-2. [

DOI:10.1179/1478422X15Z.000000000357]

10. Abyani M, Bahaari MR. A new approach for finite element based reliability evaluation of offshore corroded pipelines. Int J Press Vessel Pip. 2021 Oct 1;193:104449. [

DOI:10.1016/j.ijpvp.2021.104449]

11. Vamvatsikos D, Allin Cornell C. Incremental dynamic analysis. Earthq Eng Struct Dyn [Internet]. 2002 Mar 1 [cited 2023 Feb 10];31(3):491-514. Available from: https://onlinelibrary.wiley.com/doi/full/10.1002/eqe.141 [

DOI:10.1002/eqe.141]

12. Mustaffa Z, Gelder P v., Dawotola AW, Yu S, Kim DK. Reliability Assessment for Corroded Pipelines in Series Considering Length-Scale Effects. Int J Automot Mech Eng. 2018; [

DOI:10.15282/ijame.15.3.2018.16.0431]

13. Kuppusamy CS, Karuppanan S, Patil S. Buckling Strength of Corroded Pipelines With Interacting Corrosion Defects: Numerical Analysis. Int J Struct Stab Dyn. 2016;16(09):1550063. [

DOI:10.1142/S0219455415500637]

14. Xie M, Wang Y, Xiong W, Zhao J, Pei X. A Crack Propagation Method for Pipelines With Interacting Corrosion and Crack Defects. Sensors. 2022; [

DOI:10.3390/s22030986] [

PMID] [

]

15. Arumugam T, Rosli MKAM, Karuppanan S, Ovinis M, Lo M. Burst Capacity Analysis of Pipeline With Multiple Longitudinally Aligned Interacting Corrosion Defects Subjected to Internal Pressure and Axial Compressive Stress. Sn Appl Sci. 2020;2(7). [

DOI:10.1007/s42452-020-2994-7]

16. Zhang H, Sun M, Zhang J, Zhang Y, Li B, Zhai K. Study on Assessment Method of Failure Pressure for Pipelines with Colony Corrosion Defects Based on Failure Location. Process 2023, Vol 11, Page 3134 [Internet]. 2023 Nov 2 [cited 2024 May 25];11(11):3134. Available from: https://www.mdpi.com/2227-9717/11/11/3134/htm [

DOI:10.3390/pr11113134]

17. Fekete G, Varga L. Extension of Pit Corrosion Effect on Pipelines. Period Polytech Mech Eng. 2011;55(1):15. [

DOI:10.3311/pp.me.2011-1.02]

18. Abyani M, Bahaari MR. Effects of correlation between the adjacent components on time dependent failure probability of corroded pipelines. Struct Infrastruct Eng [Internet]. 2020;0(0):1-14. Available from: [

DOI:10.1080/15732479.2020.1811990]

19. Ossai CI, Boswell B, Davies IJ. Predictive Modelling of Internal Pitting Corrosion of Aged Non-Piggable Pipelines. J Electrochem Soc. 2015;162(6):C251-9. [

DOI:10.1149/2.0701506jes]

20. Nizamani Z, Mustaffa Z, Wen LL. Determination of Extension of Life of Corroded Offshore Pipelines Using Form and Monte Carlo Structural Reliability. 2015; [

DOI:10.14264/uql.2016.553]

21. Hou X, Wang Y, Zhang P, Qin G. Non-Probabilistic time-varying reliability-based analysis of corroded pipelines considering the interaction of multiple uncertainty variables. Energies. 2019;12(10). [

DOI:10.3390/en12101965]

22. Cui J. Studying Corrosion Failure Prediction Models and Methods for Submarine Oil and Gas Transport Pipelines. Appl Sci. 2023;13(23):12713. [

DOI:10.3390/app132312713]

23. Capula Colindres S, Méndez GT, Velázquez JC, Cabrera-Sierra R, Angeles-Herrera D. Effects of depth in external and internal corrosion defects on failure pressure predictions of oil and gas pipelines using finite element models. Adv Struct Eng. 2020 Oct 1;23(14):3128-39. [

DOI:10.1177/1369433220924790]

24. Abyani M, Karimi M, Shahgholian-Ghahfarokhi D. Failure assessment of corroded offshore pipelines using code-based approaches and a combination of numerical analysis and artificial neural network. Int J Press Vessel Pip [Internet]. 2024;209(April):105194. Available from: [

DOI:10.1016/j.ijpvp.2024.105194]

25. Soomro AA, Mokhtar AA, Kurnia JC, Lashari N, Lu H, Sambo C. Integrity assessment of corroded oil and gas pipelines using machine learning: A systematic review. Eng Fail Anal. 2022 Jan 1;131:105810. [

DOI:10.1016/j.engfailanal.2021.105810]

26. Ossai CI. A Data-Driven Machine Learning Approach for Corrosion Risk Assessment-A Comparative Study. Big Data Cogn Comput [Internet]. 2019 Jun 1 [cited 2025 Jul 20];3(2):1-22. Available from: [

DOI:10.3390/bdcc3020028]

27. Cai J, Jiang X, Yang Y, Lodewijks G, Wang M. Data-Driven Methods to Predict the Burst Strength of Corroded Line Pipelines Subjected to Internal Pressure. J Mar Sci Appl. 2022; [

DOI:10.1007/s11804-022-00263-0]

28. Zhang P, Venketeswaran A, Bukka SR, Sarcinelli E, Lalam N, Wright R, et al. Machine Learning Data Analytics Based on Distributed Fiber Sensors for Pipeline Feature Detection. 2023; [

DOI:10.1117/12.2663225]

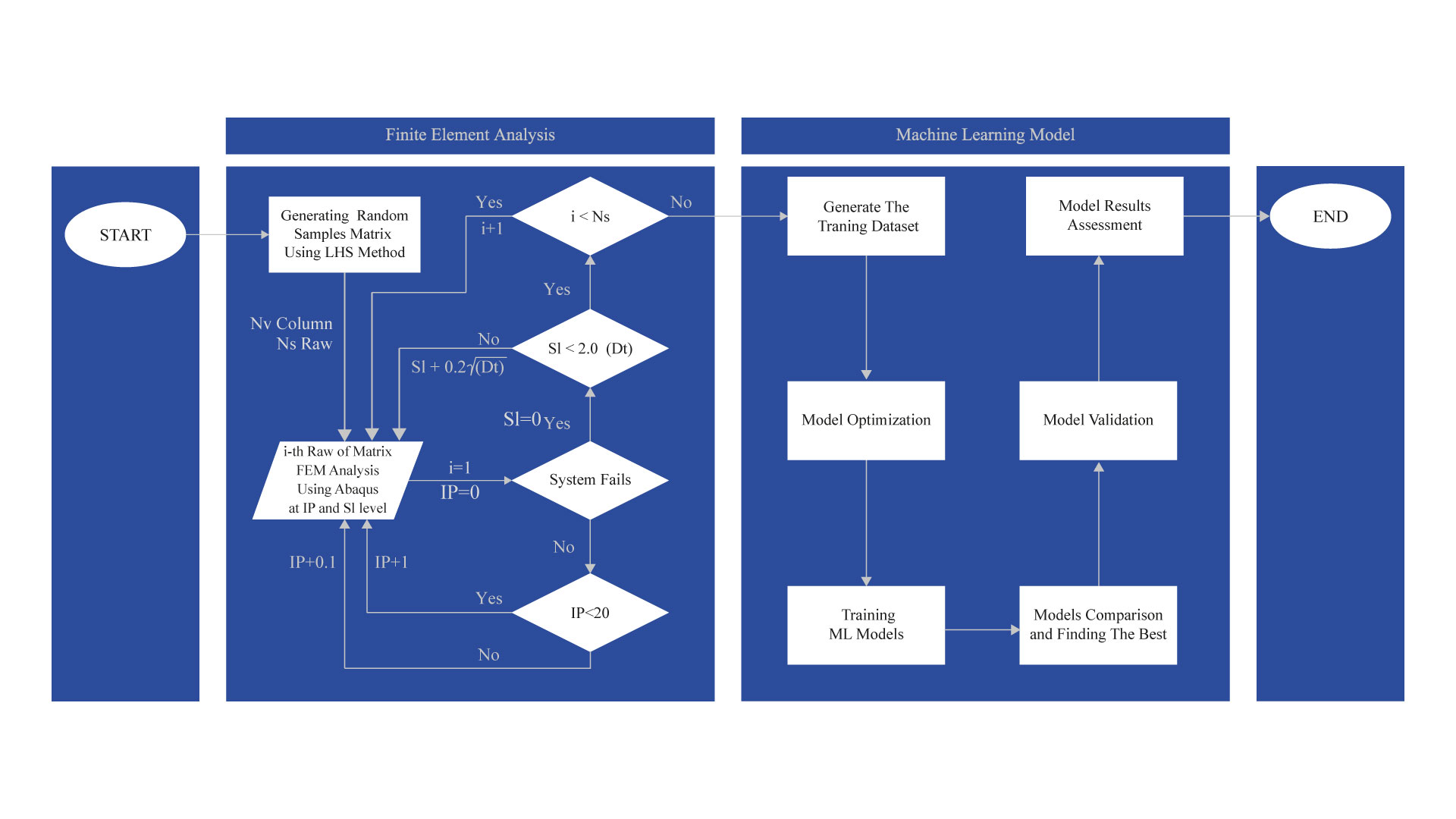

29. Abyani M, Bahaari MR, Zarrin M, Nasseri M. Predicting failure pressure of the corroded offshore pipelines using an efficient finite element based algorithm and machine learning techniques. Ocean Eng. 2022 Jun 15;254:111382. [

DOI:10.1016/j.oceaneng.2022.111382]

30. Biswas S, Rajan H. Fair Preprocessing: Towards Understanding Compositional Fairness of Data Transformers in Machine Learning Pipeline. 2021; [

DOI:10.1145/3468264.3468536]

31. Aditiyawarman T, Setiawan Kaban AP, Soedarsono JW. A Recent Review of Risk-Based Inspection Development to Support Service Excellence in the Oil and Gas Industry: An Artificial Intelligence Perspective. Asce-Asme J Risk Uncert Engrg Sys Part B Mech Engrg. 2022; [

DOI:10.1115/1.4054558]

32. Zhang C, Ye Z. Water Pipe Failure Prediction Using AutoML. Facilities. 2020; [

DOI:10.1108/F-08-2019-0084]

33. McKay MD, Beckman RJ, Conover WJ. A Comparison of Three Methods for Selecting Values of Input Variables in the Analysis of Output from a Computer Code. Technometrics. 1979 May;21(2):239. [

DOI:10.2307/1268522]

34. Abyani M, Bahaari MR. A comparative reliability study of corroded pipelines based on Monte Carlo Simulation and Latin Hypercube Sampling methods. Int J Press Vessel Pip [Internet]. 2020;181(August 2019):104079. Available from: [

DOI:10.1016/j.ijpvp.2020.104079]

35. Hosseinzadeh S, Bahaari MR, Abyani M. Reliability Assessment for pipelines corroded by longitudinally aligned defects. Ocean Eng. 2024; [

DOI:10.1016/j.oceaneng.2024.118625]

36. Zhang P, Su L, Qin G, Kong X, Peng Y. Failure probability of corroded pipeline considering the correlation of random variables. Eng Fail Anal [Internet]. 2019 May 1 [cited 2021 Jul 17];99(February):34-45. Available from: [

DOI:10.1016/j.engfailanal.2019.02.002]

37. Leira BJ, Næss A, Brandrud Næss OE. Reliability analysis of corroding pipelines by enhanced Monte Carlo simulation. Int J Press Vessel Pip. 2016;144:11-7. [

DOI:10.1016/j.ijpvp.2016.04.003]

38. Teixeira AP, Palencia OG, Soares CG. Reliability Analysis of Pipelines With Local Corrosion Defects Under External Pressure. J Offshore Mech Arct Eng. 2019; [

DOI:10.1115/1.4042384]

39. Zarrin M, Asgarian B, Abyani M. Probabilistic seismic collapse analysis of jacket offshore platforms. J Offshore Mech Arct Eng [Internet]. 2018 Jun 1 [cited 2025 Aug 30];140(3):1-11. Available from: https://dx.doi.org/10.1115/1.4038581 [

DOI:10.1115/1.4038581]

40. Hosseinzadeh S, Bahaari MR, Abyani M. Corrosion Defects Interaction Impact on Failure Pressure of Offshore Pipelines. In: ICOPMAS 2022. 2022.

41. Idris NN, Mustaffa Z, Ben Seghier MEA, Trung NT. Burst capacity and development of interaction rules for pipelines considering radial interacting corrosion defects. Eng Fail Anal. 2021 Mar 1;121. [

DOI:10.1016/j.engfailanal.2020.105124]

42. Bai Y, Yu Z. Pipeline On-Bottom Stability Analysis Based on FEM Model. Proc Int Conf Offshore Mech Arct Eng - OMAE [Internet]. 2011 Oct 31 [cited 2023 Feb 28];4:329-33. Available from: /OMAE/proceedings-abstract/OMAE2011/44366/329/357531 [

DOI:10.1115/OMAE2011-49384]

43. Song B, Sanborn B. Relationship of compressive stress-strain response of engineering materials obtained at constant engineering and true strain rates. Int J Impact Eng. 2018 Sep 1;119:40-4. [

DOI:10.1016/j.ijimpeng.2018.05.001]

44. Hosseinzadeh S, Bahaari M, Abyani M, Taheri M. Data-Driven Remaining Useful Life Estimation of Subsea Pipelines Under Effect of Interacting Corrosion Defects. Appl Ocean Res. 2025; [

DOI:10.2139/ssrn.4938846]

45. Zhang YM, Tan TK, Xiao ZM, Zhang WG, Ariffin MZ. Failure assessment on offshore girth welded pipelines due to corrosion defects. Fatigue Fract Eng Mater Struct [Internet]. 2016 Apr 1 [cited 2023 Feb 27];39(4):453-66. Available from: https://onlinelibrary.wiley.com/doi/full/10.1111/ffe.12370 [

DOI:10.1111/ffe.12370]

46. Mondal BC, Dhar AS. Burst pressure of corroded pipelines considering combined axial forces and bending moments. Eng Struct [Internet]. 2019 May 1 [cited 2023 Feb 24];186:43-51. Available from: http://dx.doi.org/10.1016/J.ENGSTRUCT.2019.02.010 [

DOI:10.1016/j.engstruct.2019.02.010]

47. Benjamin AC, Vieira RD, Diniz JLC, Freire JLF, De Andrade EQ. Burst Tests on Pipeline Containing Interacting Corrosion Defects. Proc Int Conf Offshore Mech Arct Eng - OMAE. 2008 Nov 11;3:403-17.

48. Kallem SR. Artificial Intelligence Algorithms. IOSR J Comput Eng. 2012; [

DOI:10.9790/0661-0630108]

49. Yves, Kodratoff., Ryszard, S. M. Machine learning: an artificial intelligence approach volume III. 1990.

50. Nelder JA. Regression Analysis by Example. Chatterjee S, Price B, editors. Biometrics [Internet]. 2023 Nov 17;35(1):355-6. Available from: http://www.jstor.org/stable/2529957 [

DOI:10.2307/2529957]

51. Pedregosa F, Varoquaux G, Gramfort A, Michel V, Thirion B, Grisel O, et al. Scikit-learn: Machine Learning in {P}ython. J Mach Learn Res. 2011;12:2825-30.

52. Stephenson WR. Simple Linear Regression. 2003.

53. Shamir O. Stochastic Gradient Descent for Non-Smooth Optimization: Convergence Results and Optimal Averaging Schemes. 2012;

54. Ighalo JO, Adeniyi AG, Marques G. Application of Linear Regression Algorithm and Stochastic Gradient Descent in a Machine‐learning Environment for Predicting Biomass Higher Heating Value. Biofuels Bioprod Biorefining. 2020; [

DOI:10.1002/bbb.2140]

55. Goldt S, Advani M, Saxe AM, Krzakala F, Zdeborová L. Dynamics of Stochastic Gradient Descent for Two-Layer Neural Networks in the Teacher-student Setup*. J Stat Mech Theory Exp. 2020; [

DOI:10.1088/1742-5468/abc61e] [

PMID] [

]

56. Zaidi NA, Squire D, Suter D. BoostML: An Adaptive Metric Learning for Nearest Neighbor Classification. 2010; [

DOI:10.1007/978-3-642-13657-3_17]

57. Hamed MM, Serrurier M, Durand N. Simultaneous Interval Regression for K-Nearest Neighbor. 2012;

58. Nodarakis N, Pitoura E, Sioutas S, Tsakalidis AK, Tsoumakos D, Tzimas G. Efficient Multidimensional AkNN Query Processing in the Cloud. 2014; [

DOI:10.1007/978-3-319-10073-9_41]

59. Enas GG. Choice of the smoothing parameter and efficiency of k-nearest neighbor classification. Vol. 12, Computers & Mathematics With Applications. 1986. p. 235-44. [

DOI:10.1016/0898-1221(86)90076-3]

60. Lamrini B. Contribution to Decision Tree Induction With Python: A Review. 2021; [

DOI:10.5772/intechopen.92438] [

PMID]

61. Reddy SRT, Malathi P. Design and Implementation of Sales Prediction Model Using Decision Tree Regressor Over Linear Regression Towards Increase in Accuracy of Prediction. 2022;

62. Guo T, Kutzkov K, Ahmed ME, Calbimonte JP, Aberer K. Efficient Distributed Decision Trees for Robust Regression. 2016; [

DOI:10.1007/978-3-319-46227-1_6]

63. Al-Mahasneh AJ, Anavatti SG, Garratt M, Pratama M. Applications of General Regression Neural Networks in Dynamic Systems. 2018;

64. Wong SF, Wong KYK. Wavelet Network for Nonlinear Regression Using Probabilistic Framework. 2004; [

DOI:10.1007/978-3-540-28648-6_117]

65. Gante D V, Silva DL, Leopoldo MP. Forecasting Construction Cost Using Artificial Neural Network for Road Projects in the Department of Public Works and Highways Region XI. 2022; [

DOI:10.3233/FAIA220084]

66. Ferreira R, Martiniano A, Ferreira A, Romero M, Sassi RJ. Container Crane Controller With the Use of a NeuroFuzzy Network. 2016; [

DOI:10.1007/978-3-319-51133-7_15]

67. Araghinejad S. Artificial Neural Networks. 2013; [

DOI:10.1007/978-94-007-7506-0_5]

68. Sarkar A, Mandal JK. Comparative Analysis of Tree Parity Machine and Double Hidden Layer Perceptron Based Session Key Exchange in Wireless Communication. 2015; [

DOI:10.1007/978-3-319-13728-5_6]

69. Tirumala SS, Narayanan A. Hierarchical Data Classification Using Deep Neural Networks. 2015; [

DOI:10.1007/978-3-319-26532-2_54]

70. Hyndman RJ, Koehler AB. Another look at measures of forecast accuracy. Int J Forecast [Internet]. 2006;22(4):679-88. Available from: https://www.sciencedirect.com/science/article/pii/S0169207006000239 [

DOI:10.1016/j.ijforecast.2006.03.001]

71. Willmott CJ, Matsuura K. Advantages of the Mean Absolute Error (MAE) Over the Root Mean Square Error (RMSE) in Assessing Average Model Performance. Clim Res. 2005; [

DOI:10.3354/cr030079]

72. Willmott CJ, Robeson SM, Matsuura K. A Refined Index of Model Performance. Int J Climatol. 2011; [

DOI:10.1002/joc.2419]

73. Zhang R, Guo Z, Meng Y, Wang S, Li S, Niu R, et al. Comparison of ARIMA and LSTM in Forecasting the Incidence of HFMD Combined and Uncombined With Exogenous Meteorological Variables in Ningbo, China. Int J Environ Res Public Health. 2021; [

DOI:10.3390/ijerph18116174] [

PMID] [

]

74. Hadjisolomou E, Stefanidis K, Herodotou H, Michaelides MP, Papatheodorou G, Papastergiadou E. Modelling Freshwater Eutrophication With Limited Limnological Data Using Artificial Neural Networks. Water. 2021; [

DOI:10.3390/w13111590]

75. Zhang Y, Wang T, Liu K, Xia Y, Lu Y, Jing Q, et al. Developing a Time Series Predictive Model for Dengue in Zhongshan, China Based on Weather and Guangzhou Dengue Surveillance Data. PLoS Negl Trop Dis. 2016; [

DOI:10.1371/journal.pntd.0004473] [

PMID] [

]

76. Fushiki T. Estimation of Prediction Error by Using K-Fold Cross-Validation. Stat Comput. 2009; [

DOI:10.1007/s11222-009-9153-8]

77. Behroozi-Khazaei N, Nasirahmadi A. A Neural Network Based Model to Analyze Rice Parboiling Process With Small Dataset. J Food Sci Technol. 2017; [

DOI:10.1007/s13197-017-2701-x] [

PMID] [

]

78. Ye H, Bellotti T. Modelling Recovery Rates for Non-Performing Loans. Risks. 2019; [

DOI:10.20944/preprints201902.0135.v1]

79. Irmawati, Chai R, Basari, Gunawan D. Optimizing CNN Hyperparameters for Blastocyst Quality Assessment in Small Datasets. Ieee Access. 2022; [

DOI:10.1109/ACCESS.2022.3196647]

80. Qi Y, Liu H, Zhao J, Xia XH. Prediction Model and Demonstration of Regional Agricultural Carbon Emissions Based on PCA-GS-KNN: A Case Study of Zhejiang Province, China. Environ Res Commun. 2023; [

DOI:10.22541/au.167826765.58428991/v1]

81. Verbeek M. Using Linear Regression to Establish Empirical Relationships. Iza World Labor. 2017; [

DOI:10.15185/izawol.336]

82. Quan J, Yan B, Sang X, Zhong C, Li H, Qin X, et al. Multi-Depth Computer-Generated Hologram Based on Stochastic Gradient Descent Algorithm With Weighted Complex Loss Function and Masked Diffraction. Micromachines. 2023; [

DOI:10.3390/mi14030605] [

PMID] [

]

83. Acharjee A, Finkers R, Visser RGF, Maliepaard C. Comparison of Regularized Regression Methods for ~Omics Data. J Postgenomics Drug Biomark Dev. 2012; [

DOI:10.4172/2153-0769.1000126]

84. Chen X, Liu Q, Tong XT. Dimension Independent Excess Risk by Stochastic Gradient Descent. Electron J Stat. 2022; [

DOI:10.1214/22-EJS2055]

85. Rani P. A Review of Various KNN Techniques. Int J Res Appl Sci Eng Technol. 2017; [

DOI:10.22214/ijraset.2017.8166]

86. Birajdar MR, Sewatkar CM. Machine Learning Approach to Predict the Thermal Performance of Closed‐loop Thermosyphon. Heat Transf. 2023; [

DOI:10.1002/htj.22866]

87. Cai C, Dong H, Wang X. Expectile c Forest: A New Nonparametric Expectile Regression Model. Expert Syst. 2022; [

DOI:10.1111/exsy.13087]

88. SUNESH, Balhara AK, Dahiya N, Himanshu, Singh RP, Ruhil AP. Machine Learning Algorithms for Predicting Peak Yield in Buffaloes Using Linear Traits. Indian J Anim Sci. 2022; [

DOI:10.56093/ijans.v92i8.122008]

89. Meybodi MR, Beigy H. New Learning Automata Based Algorithms for Adaptation of Backpropagation Algorithm Parameters. Int J Neural Syst. 2002; [

DOI:10.1142/S012906570200090X] [

PMID]

90. Araya SN, Fryjoff-Hung A, Anderson A, Viers JH, Ghezzehei TA. Advances in Soil Moisture Retrieval From Multispectral Remote Sensing Using Unoccupied Aircraft Systems and Machine Learning Techniques. Hydrol Earth Syst Sci. 2021; [

DOI:10.5194/hess-2020-271]

91. Jiang D, Xu Y, Yang L, Gao J, Wang K. Forecasting Water Temperature in Cascade Reservoir Operation-Influenced River With Machine Learning Models. Water. 2022; [

DOI:10.3390/w14142146]

92. Pant J, Pant P, Bhatt AK, Pant H V, Pandey N. Feature Selection Towards Soil Classification in the Context of Fertility Classes Using Machine Learning. Int J Innov Technol Explor Eng. 2019;

93. 93 -Huang F, Zhang Y, Zhang Y, Shangguan W, Nourani V, Li Q, et al. Towards Interpreting Machine Learning Models for Predicting Soil Moisture Droughts. Environ Res Lett. 2023; [

DOI:10.1088/1748-9326/acdbe0]

94. Zhang Y, Dian Y, Zhou J, Peng S, Hu Y, Hu L, et al. Characterizing Spatial Patterns of Pine Wood Nematode Outbreaks in Subtropical Zone in China. Remote Sens. 2021; [

DOI:10.3390/rs13224682]